Expert Knowledge and Analysis to Create Transparency at Asset Level

With robotron*IPEA (Industrial Process and Energy Analytics) we offer you quick and easy access to the world of Industry 4.0 and Industrial IoT. This Big Data platform is extremely flexible and versatile. It is a data evaluation tool that can be expanded at any time to increase process transparency, reducing production costs and increasing efficiency. The two modules Proactive Maintenance and ISO 50001 for Energy Management can be used individually or in combination.

robotron*IPEA is part of the federal support for energy efficiency in business. Under this program, companies can receive government funding of up to €15 million for software solutions to support an energy or environmental management system.

The solution enables direct and indirect greenhouse gases in production to be analyzed and made available for evaluations, e.g. as CO2 consumption per product, plant or process step. robotron*IPEA thus supports bottom-up scope 1 and scope 2 considerations of the common GHG standards.

Module: Proactive Maintenance

robotron*IPEA is designed for maintenance managers and engineers who want to secure the longest possible equipment availability and highest productivity. This software solution uses machine learning to conveniently carry out automated anomaly detection for each process step. Maintenance staff are then proactively notified before a problem occurs.

You as the user determine the granularity of plant integration and data evaluation. Alarms facilitate process monitoring with customized reports with both providing an overview. They also assist in finding the best possibilities for improvement measures. By linking time series and machine data, the current status of your production plant and the relationships between individual parameters can be displayed transparently. robotron*IPEA makes it possible to compare your plants with each other.

Module: ISO 50001 for Energy Management

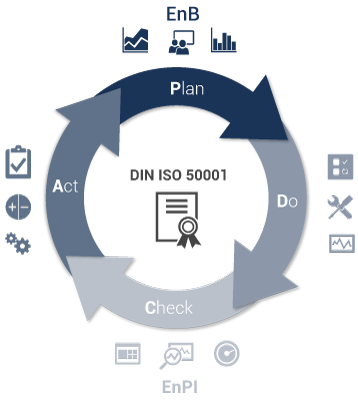

robotron*IPEA is beneficial for energy managers and energy engineers with the goal of obtaining or extending ISO-50001 certification. The software solution enables ISO 50001 compliant energy analyses on plant down to the component level, even in second intervals. In addition, an extendable ISO 50001 report can be generated.

robotron*IPEA supports the identification of Significant Energy Users (SEU), the creation of energy baseline and performance indicators (EnB and EnPIs), and the complete management of measures with Energy Performance Improvement Actions (EPIA) for effective energy management. Convenient interfaces allow individual evaluations and email notifications are sent when a threshold value is exceeded. Production systems and components can be easily compared with each other and to the state of production.

One example for the successful use of robotron*IPEA is the monitoring of performance indicators at Infineon in Dresden.

An Overview of the Advantages

- Support of proactive maintenance

- Transparency from the factory to the component level

- Benchmarking of plants and processes

- Independent of the automation depth of your production

- Integration of all physical measured variables (energy, pressure, temperature etc.)

- Detection of optimization potentials

- Monitoring of measures for optimization

- Analysis of atypical process sequences down to the individual event

- Support of energy management according to ISO 50000 family of standards

- Identification of energy efficiency potentials

- Comparison of current and historical data

Technology at its best

robotron*IPEA supports various import and export interfaces as well as file formats. The data transfer can be encrypted upon request. Store your data on-premises or outsource it to an external data center or the cloud. It is also possible to acquire and process data in combination with our innovative IoT field gateway RoboGate. For any case, you decide on the intensity of support, regularity of the updates or the implementation of custom solutions. All of your requests are carried out by our reliable service and maintenance team.

Further Features

- Individual design of dashboards, reports and notifications

- Configurable user management

- Integrated data archiving

We look forward to hearing from you!

We will be happy to answer your questions and provide you with individual advice.